Resin Flexible Steel Plates For Elegoo Mars/Anycubic Photon/Photon Mono/SE/ Mono X

$9.90 – $17.80

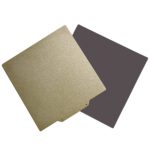

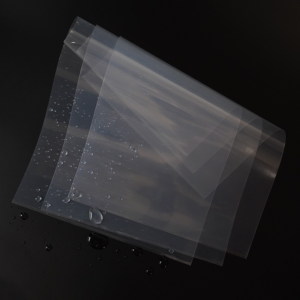

Resin Flexible Steel Plates Good quality product: Made of high-quality resin material, durable and long service life. it can be used for a long time.

Convenient and easy to use: Easy to install and remove, no tools required. it can be used in a variety of applications such as home, office, business, etc.

Safe & secure checkout

Order Info

Order today, ships in 24 hours(working days)

Also bought together

- Description

- Additional information

Description

Applicable printer(Tested) :

135*80mm:

Anycubic Photon/S/SE/Mono

QIDI Shadow 5.5s

140*84mm:

Elegoo Mars 2 Pro

Creality LD-002H

Nova 3d Bene 4

135*75mm:

Elegoo Mars/Pro

Phrozen Sonic Mini 4k

Monoprice Mini Deluxe SLA

Wanhao D7

202*128mm:

Anycubic Photon Mono X

Anycubic Photon X

SainSmart KL-9

How to install the flexible steel plate?

Additional information

| Weight | 0.5 kg |

|---|---|

| Spring Steel Sheet | 138*78mm, 204*129mm, 224*129mm, 135*75mm, 135*80mm, 140*84mm, 150*95.6mm, 168*90mm, 172*110mm, 192*120mm, 202*128mm, 200*125mm, 238*128mm |

.jpg)

Fairly pleased with this product. I doubt the difference between the next competitor and this one is worth the $ increase. I’ve had good adhesion to the build plate every time, magnet pad is 3M brand adhesive if that matters to anyone. I’ve noticed a fine layer of resin about 1/4” to 1/2” around the border between the magnet and the plate so it’s probably lifting a bit. I don’t usually print super close to the edges and even if you did I’m betting theres some capillary action pulling the thing in. I do recommend what someone else did, use some clamps and a board to install the thing firmly to the original build plate.

Much like most things in a hobby like this, it needed a fine adjustment. I just needed to sand the plate so that the prints would stick a little better. Works great.

Just make sure you let dry for 3 days

My first two prints with this were total failures sticking to the FEP. Once I sanded the magnetic build plate prints finally stuck. I suggest 220 – 400 grit sandpaper.

I have not experienced any flex wile printing. Stand flat threw the entire printing process.